About the AUTOMOTIVE LUBRICANTS market

Practical and robust!

From 2D design to 3D modelling, Berry Astrapak's new creative hub aims to deliver more than expected and push the creative boundaries in every dimension. We offer a variety of market-tested manufacturing process for automotive lubricants packaging. Manufacturing processes are selected according to design, cost, manufacturing speed and volume considerations.

As automotive lubricants packaging design gets more sophisticated, so does decoration. Berry Astrapak offers a full range of decoration solutions to ensure brand integrity and recognition.

Bottles

Berry Astrapak offers a variety of market tested manufacturing process for automotive packaging. Manufacturing processes are selected according to design, cost, manufacturing speed and volume considerations. Extrusion Blow Moulding is the process used to manufacture automotive containers. Injection Blow Moulding is used for the production of hollow plastic containers in large quantities. These are typically bottles and jars with unusual designs, while Injection Stretch Blow Moulding involves using an injection moulded preform, which already carries the neck of the bottles, including threads, on one end. ISBM is used to manufacture products where strength and clarity are a prerequisite.

Features

Spouts designed to work in tandem with 28mm and 38mm closures

Handles facilitate carrying and pouring

Clip-on decorations for unique appeal

Visi stripe technology

Application

Lube Oils

Brake Fluids

Antifreeze

Gear Oil

Car Care Products

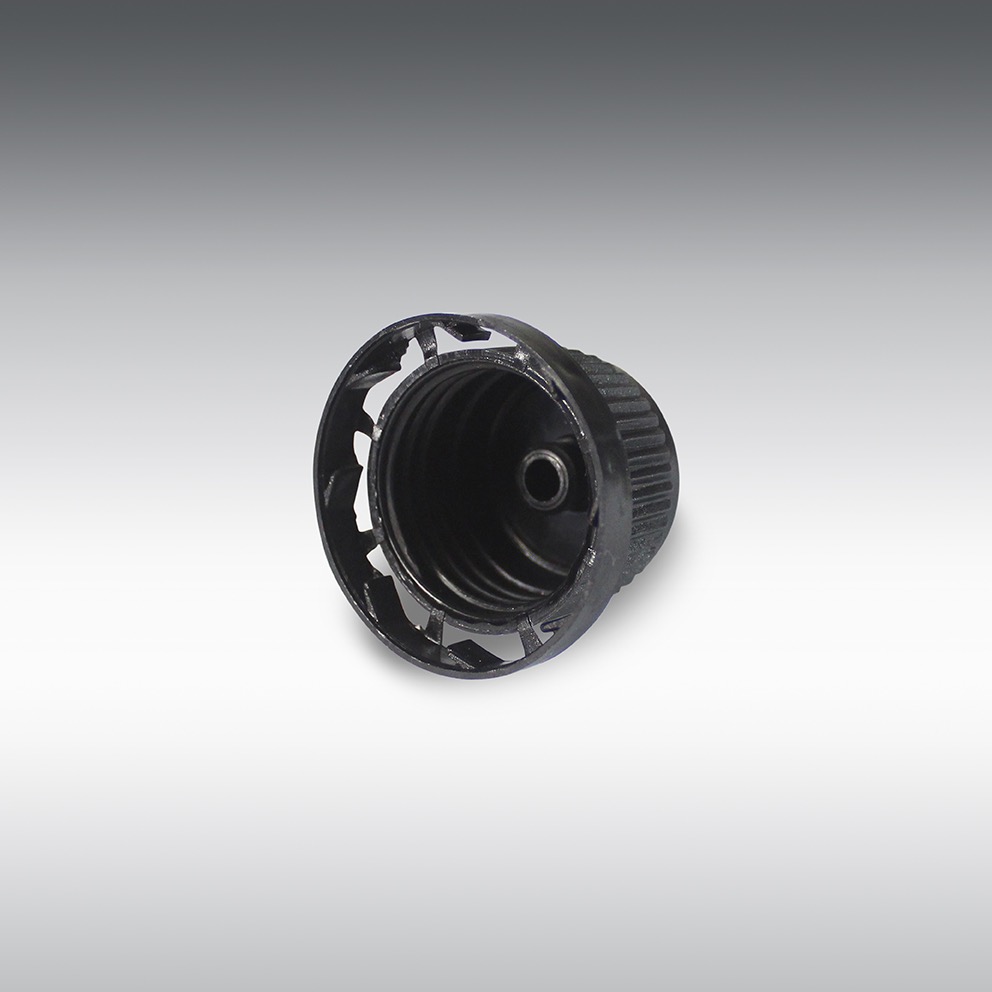

Functional Components

Berry Astrapak has the capacity to improve product performance, delivery, traceability and consumer approval of automotive products through the addition of a range of functional components. Injection Moulding is a versatile manufacturing process for producing precision components for critical functions such as closures, spouts and tubs.

Spouts are designed to work in tandem with 28mm and 38mm closures. Ideal for use with gear oils, hydraulic fluids and general lubricants and can be retracted into the bottle after use.

Handles are designed to assist in transport and delivery of the product. The latest designs feature dual handles to facilitate carrying and pouring.

Clip-on Decorations can be separately injection moulded and clipped on to provide unique designs and brand differentiation.

Visi Stripe Technology can be incorporated into the manufacturing process for customer convenience.

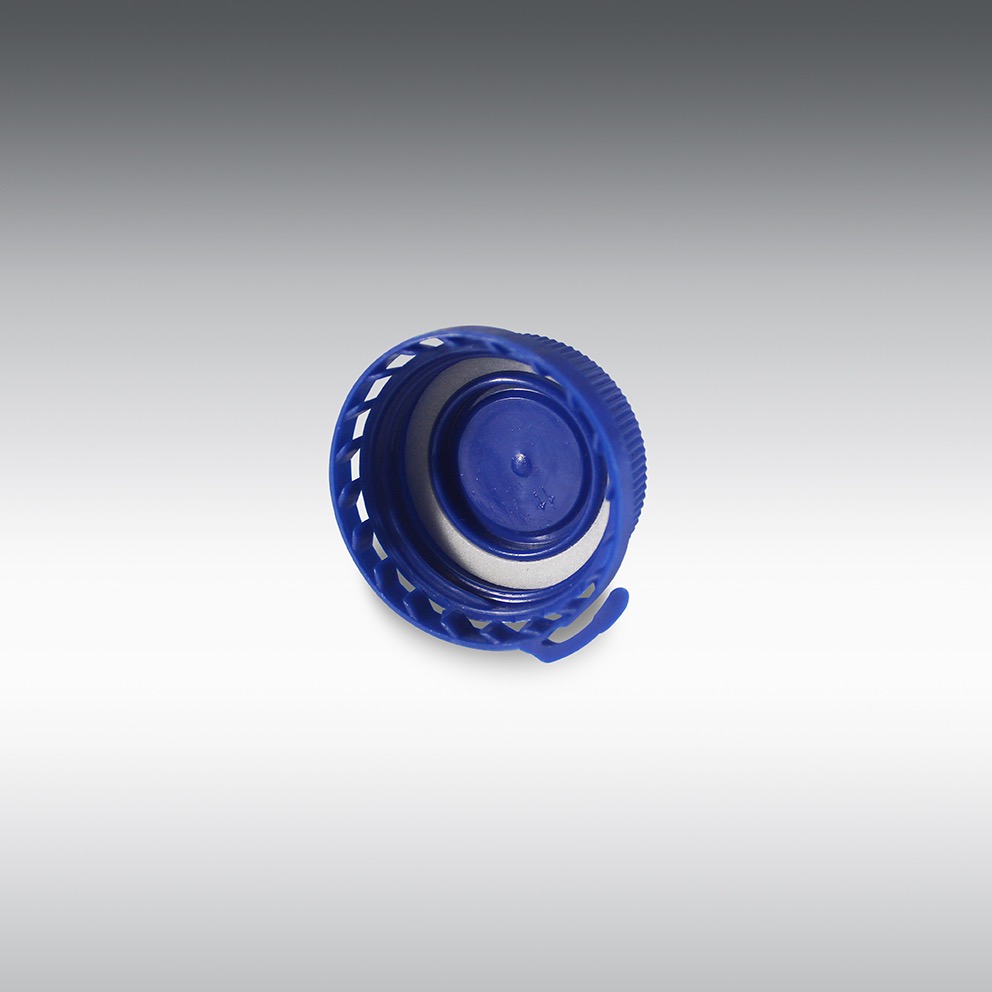

Closure Options

Berry Astrapak manufactures a wide range of closures for the automotive industry in 28mm, 38mm, 40mm and 52mm. Closures come in any colour and can be manufactured to match the bottle and or label design. All Moulding automotive closures are tamper-evident and produced in advanced injection moulding systems. Customised closures can be supplied with logos or branding features to improve product identity and increase consumer recognition.

Features

Closes container, keeps contents intact

Barrier to dirt, oxygen, moisture

Assists in dispensing and use of product

Easy to open and tamper-evident

Combat product counterfeiting

Application

Available in 28mm, 38mm, 40mm and 52mm